声波所至 服务随行

高精密度超声波焊接设备品牌厂家

High precision ultrasonic welding equipment brand manufacturer高精密度超声波焊接设备品牌厂家

High precision ultrasonic welding equipment brand manufacturer

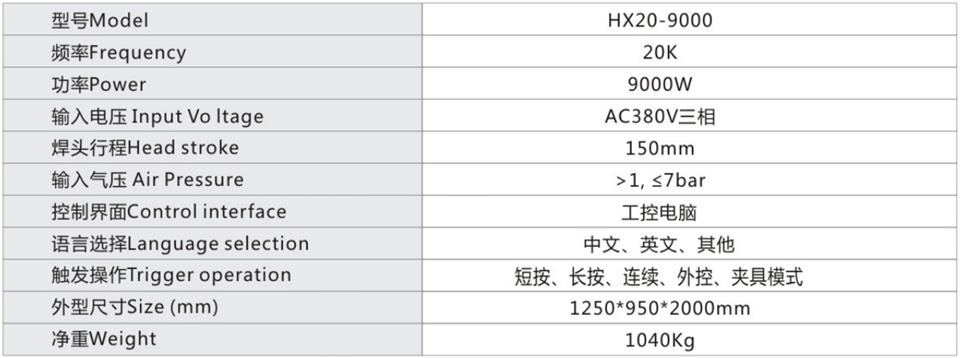

● 全新设计扫频追频线路,可在0.05秒内扫频并锁定,极大程度降低了换能器与模具在开机扫频时的不必要损伤;

● 系统升级至恒定振幅线路,不受外部电压的变化影响,始终保持工作时的高压、高振幅输出;

● The newly designed frequency scanning and tracking circuit can scan and lock the frequency within O.05 seconds, greatly reducing unnecessary damage to the transducer and mold during startup frequency scanning; The system is upgraded to a constant amplitude circuit, unaffected by external voltage changes, and always maintains high voltage and high amplitude output during operation;

● The system adopts a constant amplitude circuit, which is not affected by external voltage changes and always maintains high voltage and high amplitude output during operation;

● 大型一体式机架,方便移动,且坚固不变形,可确保焊接时机头不变形后仰;

● 配置品牌电器元件,气压精度可控0.01bar有效保证焊接精度;

● 搭载安全防压透明工作门,时实的观察焊接的工作状态,同时与有效确保操作者的人身安全;

● 整机动作由多点位PLC控制,保证操作的流畅性;

● 搭配电子磁栅尺及压力传感器可实现绝对深度与相对深度的精准控制(0.01mm);

● 配备多种焊接模式(时间、能量、功率、绝对深度、相对深度)可兼顾多种不同焊接应用;

● 可同时开启或单独使用焊接时的品质监控;

● 可接入MES系统实时上传焊接数据,可扩展至上位机功能并支持扫码对应记录数据;

● 实时显示焊接曲线,可直观了解焊接时的动态走向;

● 可存储多组自命名的焊接数据,便于操作人员查找;

● 可存储多条焊接记录,可导出至PC端便于品质管理的追溯查找;

● 装配精密多功能全自动底模,可有效解决端子摆放和电缆线的定位,可保证焊接时的品质与外观;

● Large integrated frame, easy to move and sturdy without deformation, ensuring that the machine head does not deform and tilt back during welding; Configure branded electrical components, with a controllable air pressure accuracy of 0.01 bar, effectively ensuring welding accuracy;

● Equipped with a safety and pressure resistant transparent working door, it can observe the working status of welding in real time and effectively ensure the personal safety of operators;

● The whole machine is controlled by a multi-point PLC to ensure smooth operation; Paired with an electronic magnetic grating ruler and pressure sensor, precise control of absolute depth and relative depth

(0.01mm) can be achieved;

● Equipped with multiple welding modes (time, energy, power, absolute depth, relative depth), it can accommodate various welding applications;

● Quality monitoring during welding can be enabled simultaneously or separately;

● It can be connected to the MES system to upload welding data in real time, and can be extended to the upper computer function and support scanning corresponding record data;

● Real time display of welding curves, allowing for intuitive understanding of the dynamic direction during welding;

● Can store multiple sets of self named welding data for easy searching by operators;

● Can store multiple welding records and export them to the PC for easy traceability and search of quality management;

● Assembling a precision multifunctional fully automatic bottom mold can effectively solve the problem of terminal placement and cable positioning, ensuring the quality and appearance of welding;